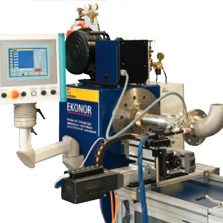

Panther

Panther

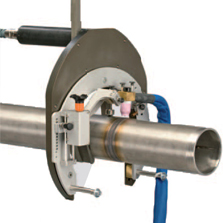

For stationary welding of flange-/formed part joints (pipe rotating)

The PANTHER pipe welding system drastically reduces overall manufacturing times, with improved seam quality and a root free of tempering discoloration.

Up to 5 mm wall thickness in one layer, without seam preparation